Two Roll Automatic Shrink Wrapper

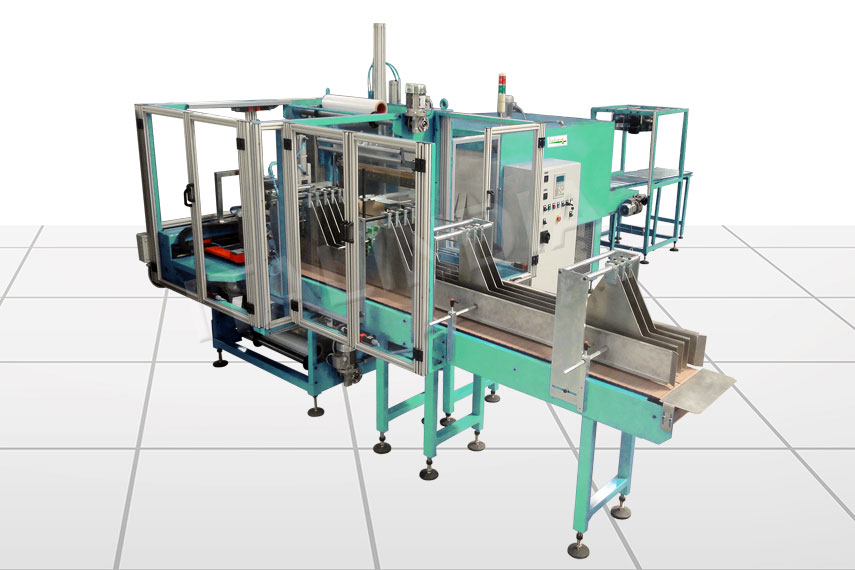

Two Roll Shrink Wrapper with multiple tracks for feeding products: Model: TR8 A 90° MT

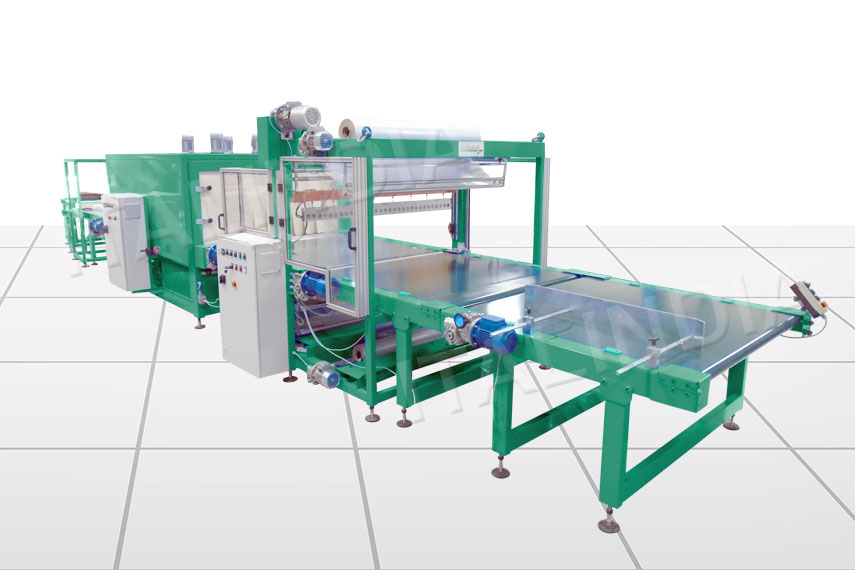

Two Roll Automatic Shrink Wrapping Machine - TR A Series

Our automatic shrink wrap machines prove as pioneering models for a widespread of industry sectors that has requirement of large scale production of small size products packaging, like food container sealing machines. Our robust manufacturing of the models offers greater reliability and assures the customers to smoothly run three shifts continuously with our products. The customer can be assured of the high quality of the components and spares, as we manufacture all the parts in-house, fabricated in our own machine shop to pledge best quality and maximum durability.

The Two Roll Shrink film packaging machine, shrink wraps products of different sizes and collations with Polyethylene/ LDPE as Shrink film. This automatic shrink wrap machine automatically detects and loads the product with the help of a frontal driven feeding belt. It is easy to connect this shrink packaging machine directly to the production line. Alternatively, it also allows the manual loading very quickly for single item products.

The automation of product loading direct from the product line to the shrink wrap equipment enhances the productivity. The flexibility of manual loading for single item products gives the versatility of utilising the automatic packing machine to the advantage of the user as per the milieu of loading.

Two Roll Shrink Wrapper: Model: TR10 A

Products are loaded with a 90° conveyor and then automatically arranged according to the required collation of bundle. This model completely automizes the collation process to offer a high production output. This packaging solution ensures to take your processes to the next level in manufacturing and production.

Another special feature of the A90° models is that the shrink wrap equipment occupy less space and the layout can be planned in such a way to receive the shrink packed products ergonomically. The design of the 90° conveyor can be made either as LH or RH as per the actual need of the customer according to their present layout in their plant. The less occupied space by the automatic shrink wrap machine, that can be accommodated as per the user’s plant outline, gives more space for the merchandise; and the layout doesn’t demand a longer linear space which can be used to the customer’s advantage.

Kissing Belt

The TR8A L shrink packaging machine is featured with a special system called Kissing Belt, that aids in smooth transit of the products over the sealing system. When very small products or unstable products or light weight products are transmitted in the conveyor over the sealing system, the kissing belt allows the product to be packed without falling or getting caught in the midst of the machine. This special feature not only saves the time of the operator in regulating the inward feeds to be wrapped but also enables the machine for incessant production without any obstacles.

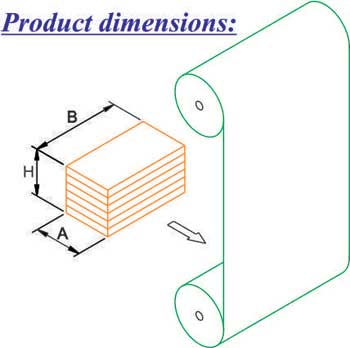

How to select TR A series shrink wrapping machines ?

As the pioneers of shrink machine manufacturers, we are able to address specific needs required by our customers and make the automatic packing machine price more affordable. Value addition is a definite experience of our customers when it comes to our shrink packaging solutions. The model of the machine can be chosen based on the measurements of the product to be shrink wrapped and following the guideline shown in the chart below.

| TR8 A | TR8A 90° | TR10 A | TR10 A 90° | |||

| Min. Dimension (in mm) | A | 250 | 70 | 250 | 100 |

|

| B | 100 | 200 | 100 | 200 | ||

| H | 50 | 70 | 50 | 80 | ||

| Max. Dimension (in mm) | A | 350 | 300 | 900 | 300 | |

| B | 580 | 500 | 800 | 600 | ||

| H | 370 | 370 | 370 | 370 | ||

| Max. B + H (in mm) | 800 | 800 | 1000 | 1000 |

To receive the perfect shrink wrap solution and your best mini packing machine price, contact us immediately.

Features of TR8 A / TR 10 A

The Two Roll Automatic Shrink Wrapping Machine is a very flexible model suitable for products of different sizes and guarantees high efficiency in the packaging process. TR8 / TR10 offers top quality packages in terms of both the sealing strength and shrinking processes to protect your products during transports. The heat shrink polyethylene film can be used to replace expensive carton packages and it can also be printed with your brand name.

This automatic shrink wrap machine provides worthwhile features that can be controlled, adjusted and regulated as per specific needs of users. The compatibility of the machine with different product dimensions, temperature settings, conveyor speed in the shrink tunnel, attuning the level of circulation of hot air in the shrink tunnel are few of the valuable features of this shrink film packaging machine. The different shrink wrap films including biodegradable shrink wrap, as preferred and chosen by the customer would be tested and features will be suggested for feasibility.

As leading automatic shrink wrap machine manufacturers, we find our customers most delighted with the value they have received for the affordable small packing machine price that was offered.

- Price advantages and Cost savings over traditional carton packing method

- Enhances your product brand loyalty and transparency

- Efficient temperature control supported by double layer insulation in the shrink tunnel

- Regulation of hot air blowing by deflectors

- Parameter adjustments to suit the required Shrink film that the customer prefer to use

-

Bottles in line

-

Bottles in matrix

-

Pack with bulls eye

-

Spice packs

-

Juice bottles

-

Water Bottles

-

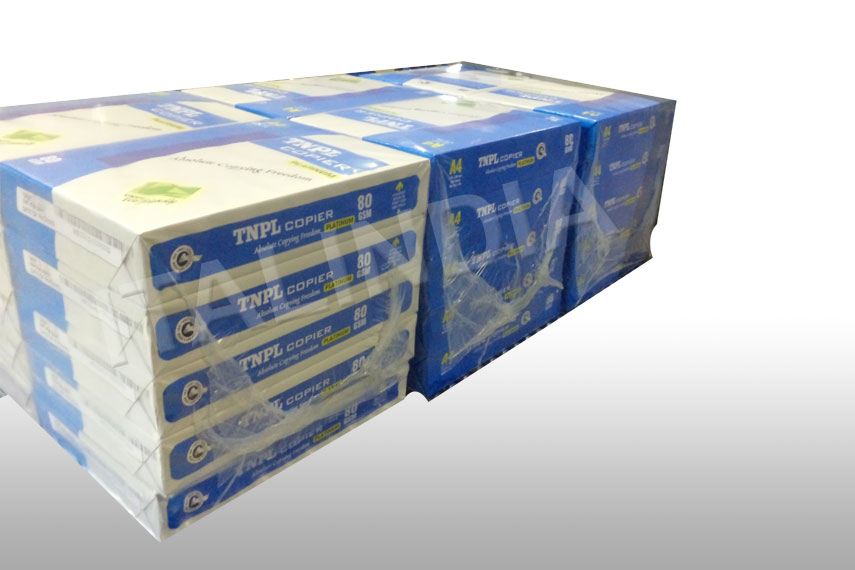

Paper Reams

Sample products

Specifications

| Film thickness (µ) | 30 -110 (PE) |

| Installed power - Machine + Standard Tunel | Model: TR8 A - 20 kW Model: TR8 A 90 - 20 kW Model: TR10 A - 27.5 kW Model: TR10 A 90 - 27 kW |